Frequently Asked Questions

What is a rebar / deformed bar / kabilya?

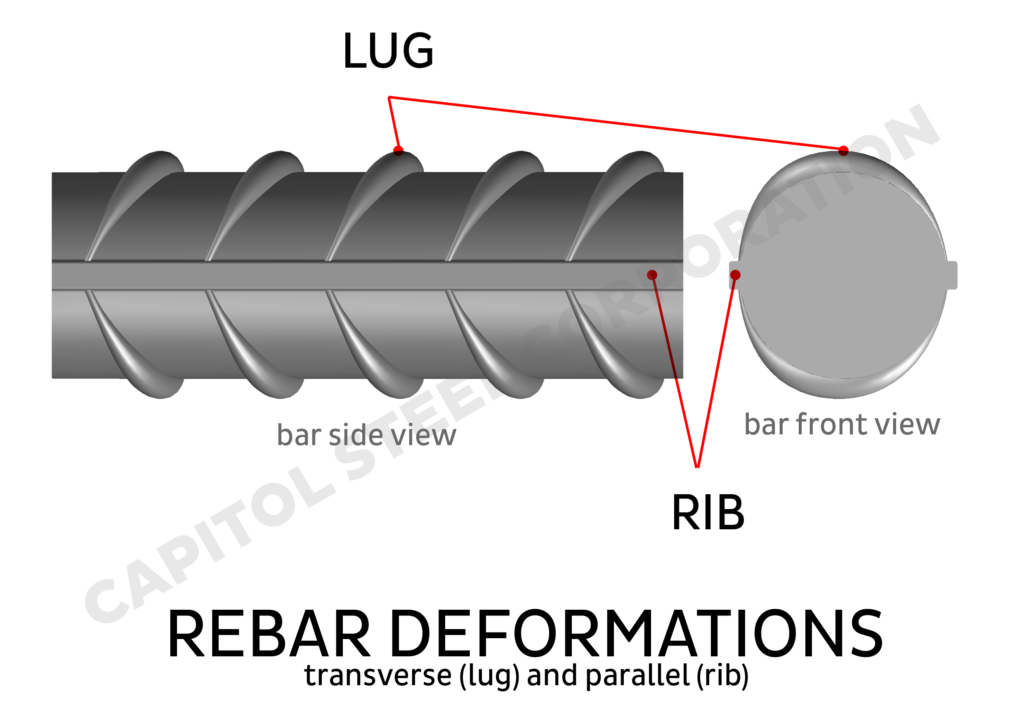

Rebars (also known as reinforcing steel bars, deformed bars or debars, concrete reinforcement bars, or in the Filipino term kabilya) are round steels bar with protrusions called deformations (see DEFORMATION in our Technical Specifications) used as tension devices in reinforced concrete to strengthen and hold the concrete together.

What is PNS 49?

Formulated by the Bureau of Philippine Standards (BPS) of the Department of Trade and Industry (DTI) with the help of the Steel Industry, the Association of Structural Engineers of the Philippines (ASEP), and the Philippine Construction Association (PCA), Philippine National Standard 49 or PNS 49, a mandatory Philippine standard, covers deformed bars manufacturing and testing in the Philippines.

What is ASTM A615? ASTM A706? How do they differ from PNS 49?

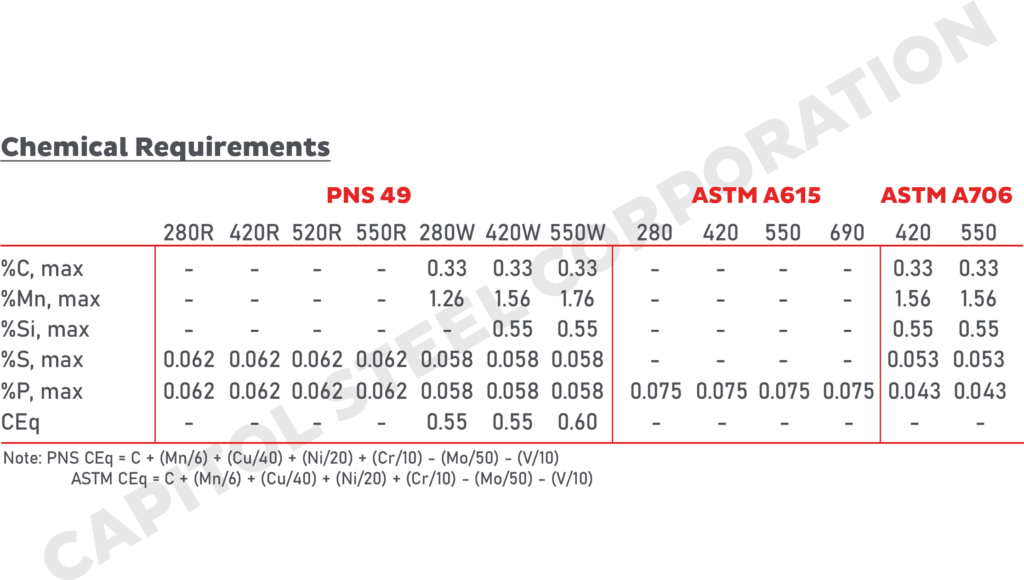

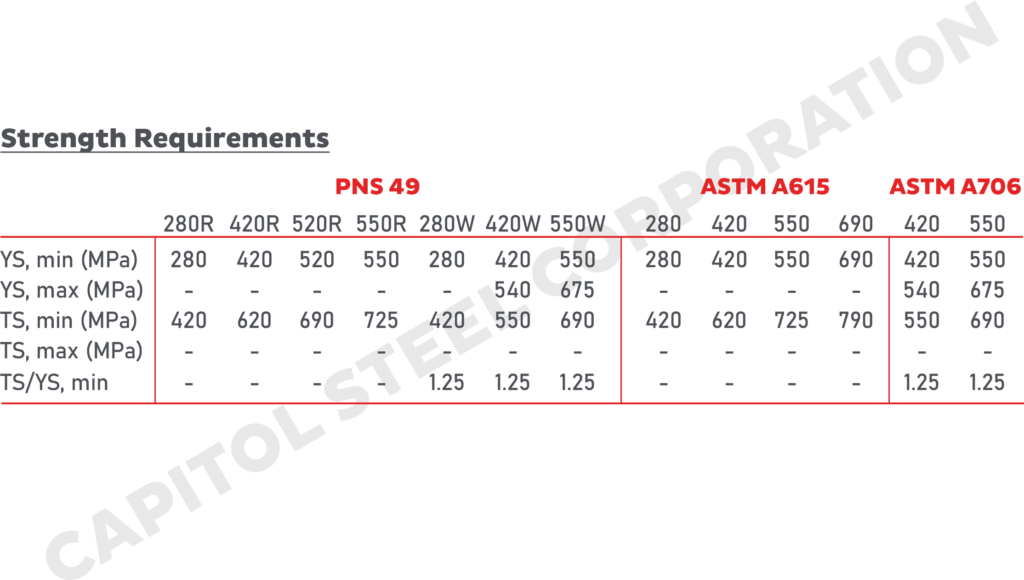

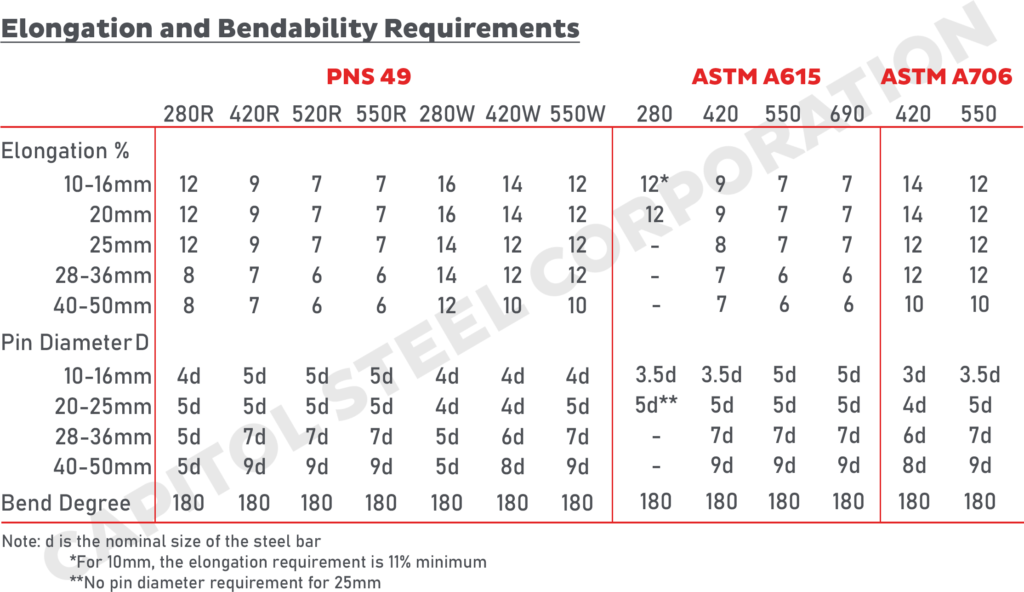

The American Society for Testing and Materials (ASTM) developed various standards agreed upon and adopted internationally by a multitude of industries. Specifically for deformed bars, ASTM A615 (Standard Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement) and ASTM A706 (Standard Specification for Deformed and Plain Low-Alloy Steel Bars for Concrete Reinforcement) prevail amongst such standards. In addition, the Philippines’ national rebar standard, PNS 49, has been aligned to these standards as much as possible. However, the seismic conditions of our country as well as the requirements of the key stakeholders introduced some distinctions between these rebar standards. Below, these tables show a comparison between the different aspect of the ASTM and PNS standards.

How do I know if the deformed bars I bought conform to PNS 49?

Check the accreditation with the Bureau of Philippine Standards (BPS) of the manufacturer involved. Certainly, BPS requires all manufacturers of deformed bars to place their distinguishing logo on every meter of their steel bars. Furthermore, BPS registers this logo in their archive. However, a manufacturer can still attempt to circumvent PNS 49 despite its accreditation. For this reason, always test two or three steel bar samples in a reputable laboratory. These PNS/ISO accredited laboratories will measure, weigh and test the yield point, tensile strength, elongation, and bending of the deformed bars. Truly, one cannot ascertain the quality of a rebar simply through visual inspection.

Where can I have my deformed bars tested?

You can test your samples at ISO/IEC 17025 accredited laboratories, for instance, the Metals Industry Research and Development Center (MIRDC) in Bicutan or the Philippine Geoanalytics Inc. (PGAI) in Quezon City, to see if it conforms to PNS 49 specifications.

What is Tension Testing?

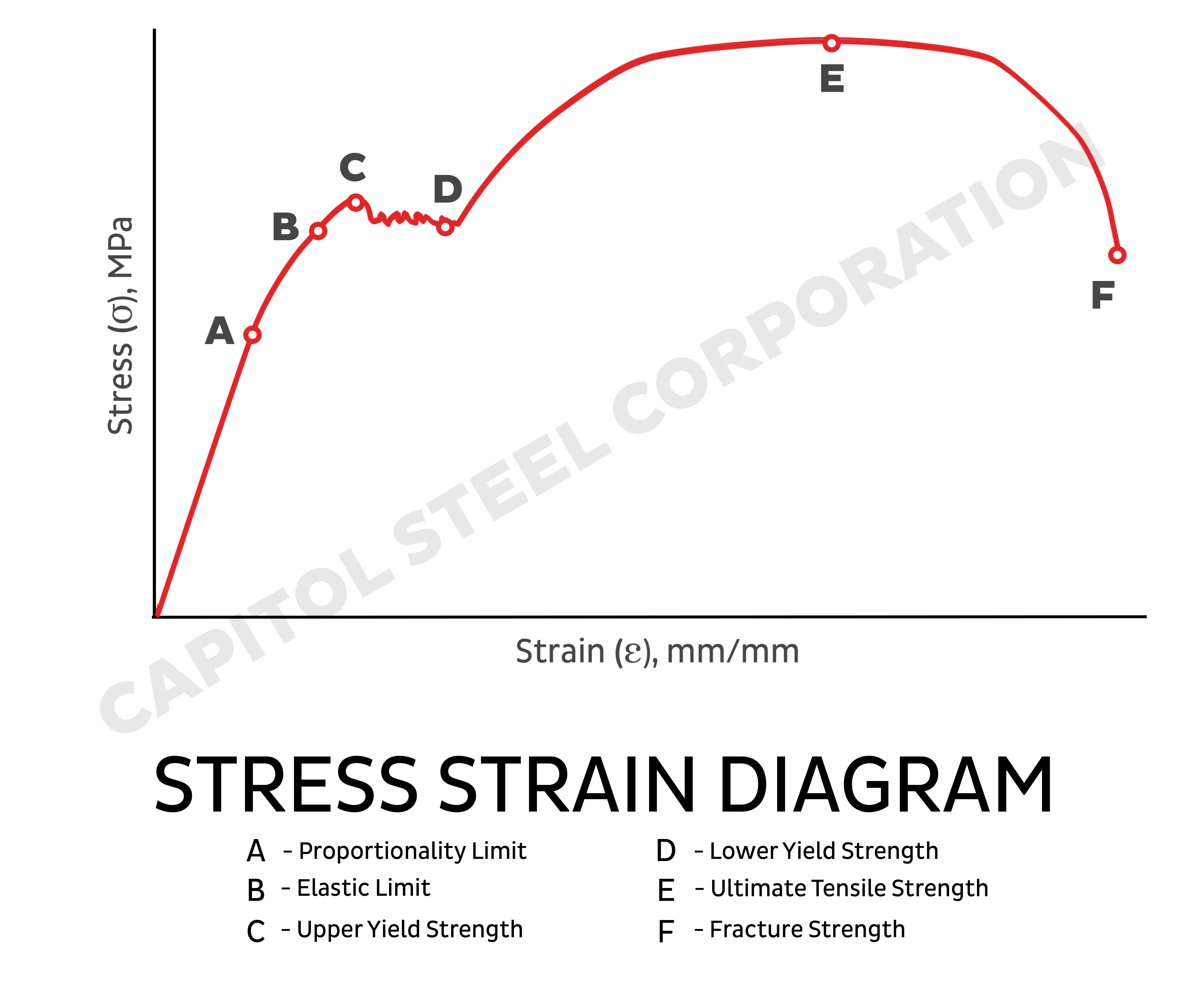

Tension testing, also called tensile testing, is material testing test performed to a rebar in which the rebar’s properties such as yield strength, ultimate tensile strength, fracture strength, elongation etc are measured directly.

A universal testing machine (UTM) applies a tensile (stretching) force to a rebar sample of certain area until it fractures. Then, the maximum pressure points wherein the rebar sample can withstand permanent uniform deformation (yield strength), permanent localized deformation (ultimate tensile strength), and inevitable fracture (fracture strength) are accounted for, usually with a graph that plots the pressure against the strain which the sample experienced.

Equally important, one must compare the dimensions of the rebar sample after the fracture from its original dimensions to calculate the percent elongation and area reduction, both measures of a rebar sample’s ductility.

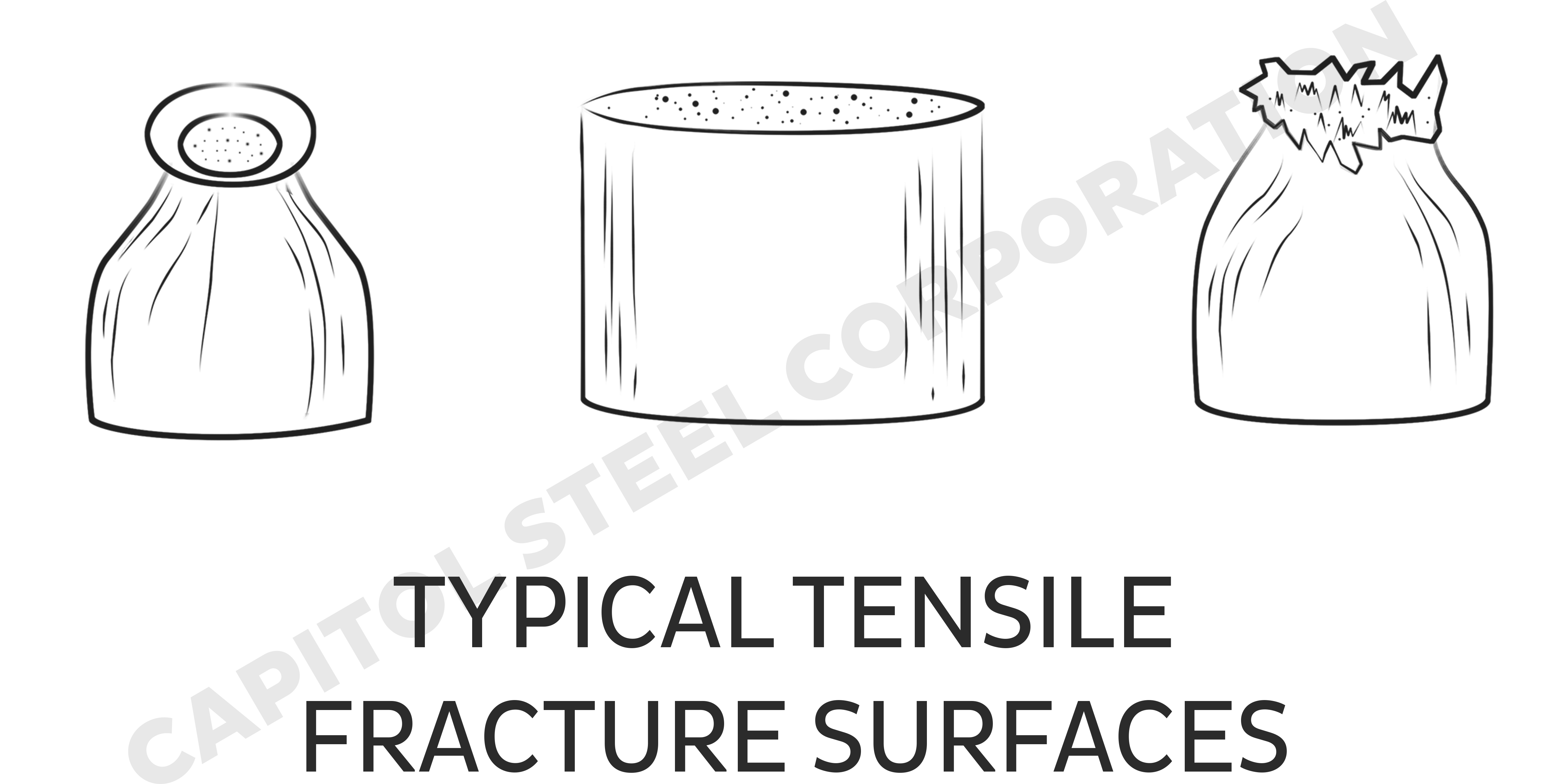

Moreover, the fracture type of the rebar sample can also give indications of the ductility/brittleness of the rebar. In particular, flat, grainy fracture surfaces imply a brittle rebar while cup-cone surfaces imply a ductile rebar. Deformed bars with irregular fractures fall in between ductile and brittle materials.

Below, a typical rebar stress-strain diagram as well the different rebar fracture surfaces are depicted.

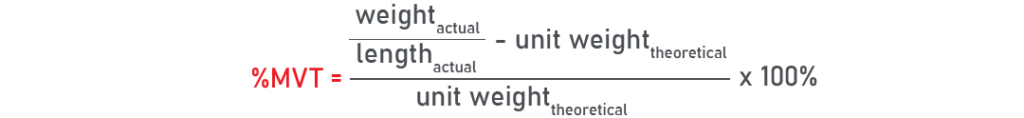

What is Mass Variation Testing?

As the name implies, mass variation testing is a type of materials testing performed on a rebar wherein the unit weight (weight per length) of a rebar sample is compared with its theoretical unit weight. PNS 49 specifies the theoretical unit mass requirement of each rebar size. To illustrate, see WEIGHT TABLE our Technical Specifications. PNS 49 allows a rebar mass variation of ±6.0 percent. In particular, the following equation computes the rebar mass variation.

Why is it important to have standard deformed bars?

In an earthquake-prone country like the Philippines, using substandard deformed bars can be life-threatening. The yield point and tensile strength ratio ensure enough “reserve energy” for the steel you use to withstand the sustained swaying motions and the subsequent aftershocks of an earthquake. Thus, ensuring the use of standard deformed bars must be a priority.

What are some practices that should concern a buyer?

For example, one common practice is to maximize the 6% weight tolerance for each rebar. Since weight deviations of 2% – 3% occur during the rolling process, undersized deformed bars are included in the production batch. Another practice is the use of unsuitable raw materials to produce deformed bars that are too brittle and cannot pass bending tests under laboratory conditions. Similarly, another practice switches the colour coding of the rebar to pass a lower grade off as a higher grade. Therefore, as a rule of thumb, never buy from a manufacturer whose selling price is more than 2% lower than other competitors. Above all, the savings involved are not commensurate to the safety risk.

How do you measure the diameter of a rebar?

The diameter of a rebar, for example 16 mm, refers to the mean nominal diameter of the cross sectional area of the rebar, core and deformations included. It is therefore a theoretical diameter which cannot be directly measured using a ruler, caliper or micrometer. The mass variation and the height of lugs of a rebar thus controls this theoretical diameter. See MASS VARIATION and DEFORMATION in our Technical Specifications.

What is rusting and how does it affect the performance of deformed bars?

Due to the reactivity of iron with oxygen, mild steel products, including steel bars, are inherently sensitive to the atmosphere. The interaction between the iron in mild steel and the oxygen in atmospheric air causes the oxidation process more commonly referred to as rusting or atmospheric corrosion in the bars.

Superficial rusting of deformed bars does not affect its performance. In fact, surface rust can increase the bond of the rebar to the concrete. However, prolonged surface rusting can eventually lead to pitting of the steel bar and this may lead to a weakening of the steel section. Weigh the cleaned suspect rebar sample to check that the section is not below the lower unit mass tolerance and tensile testing undertaken to ensure that the physical properties are still above the minimum requirements.

You can find more information about rusting and its effect on deformed bars here.

What is the smallest bend radius that we can bend a rebar?

PNS 49 specifies the minimum pin diameter for the inside bend diameters of the various rebar sizes and grades. See PIN DIAMETER in our Technical Specifications.

What are quenched and tempered (QT) rebars?

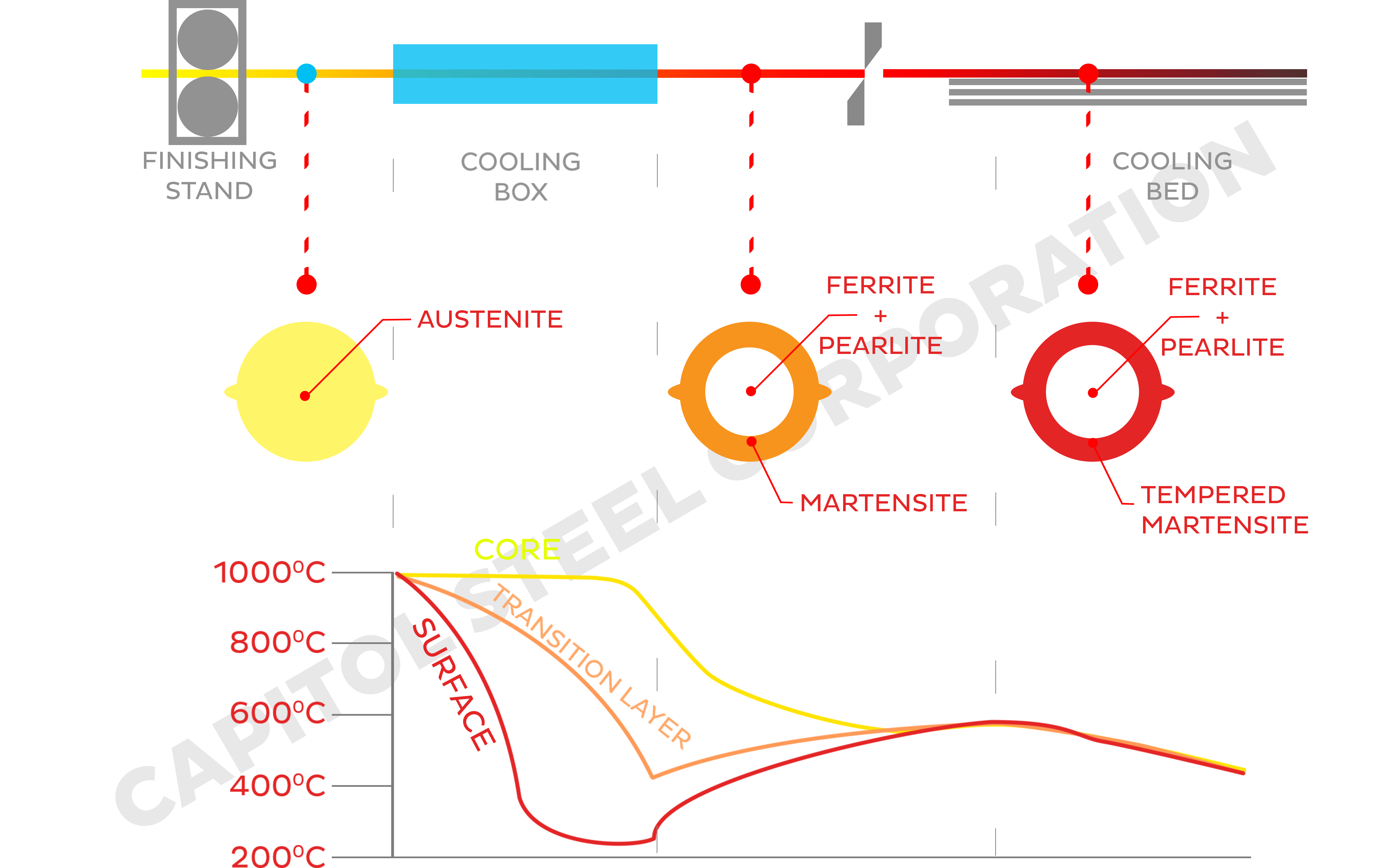

Quenched-tempered (generally known as quenched and tempered (QT) or quenched and self tempered (QST), but also sometimes mistakenly called as TEMPCORE™ in reference to one of the earliest trademarked QT process) deformed bars are manufactured through a thermomechanical process called quenching and tempering. This process involves the rapid, superficial cooling of a hot-rolled rebar (quenching) and then the subsequent reheating through the residual core heat (tempering). Quenched-tempered steel bars have higher strength and toughness than simple hot-rolled deformed bars.

QUENCHING & TEMPERING

Process Overview

QUENCHING & TEMPERING

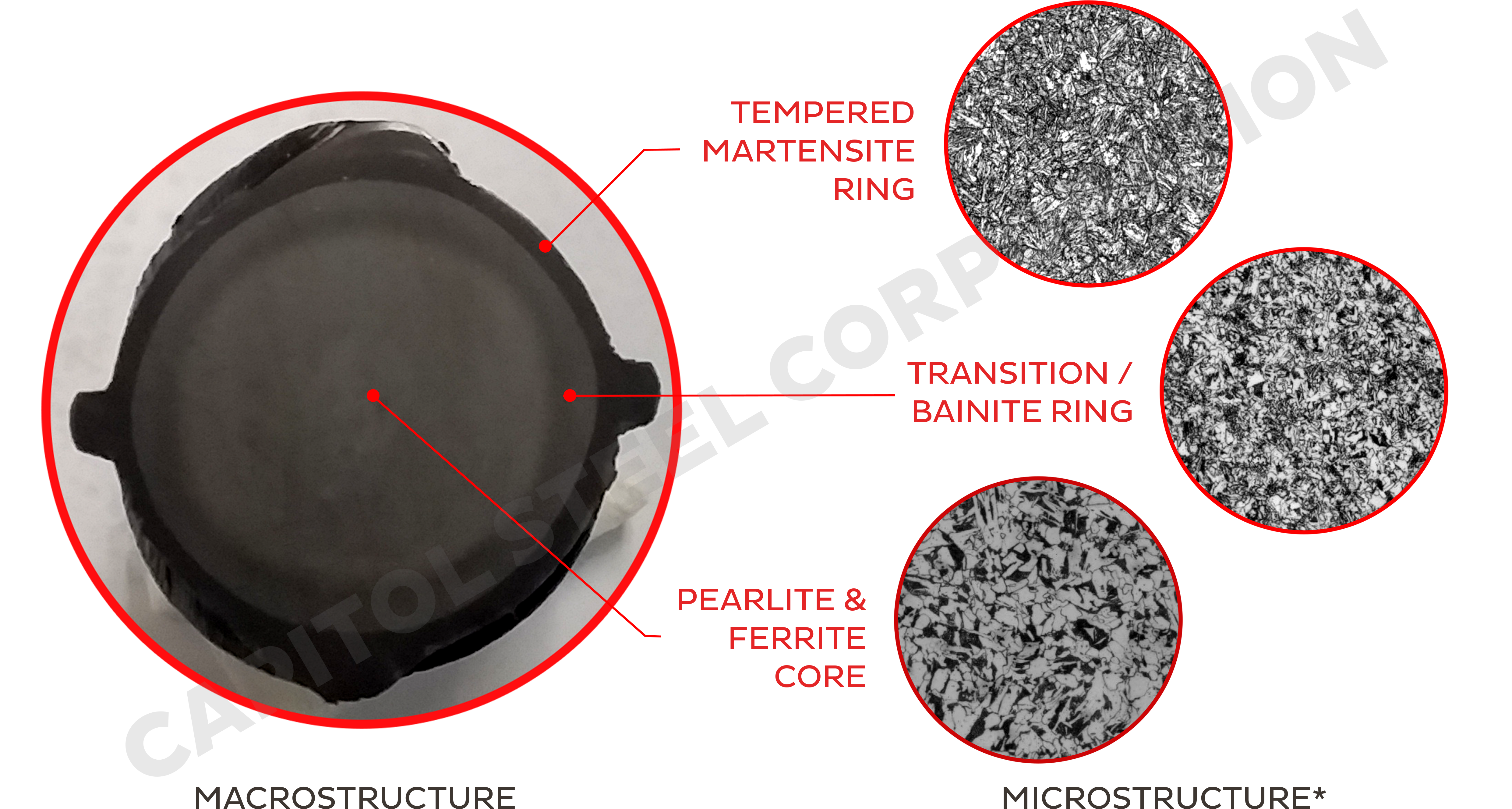

Structure of a QST bar

The quenching and tempering process forms the tempered martensite layer from which the higher strength derives from. Similarly, the bainite transition layer contributes to the bars improved toughness. The pearlite-ferrite core, keeps the ductility of the bars.

Learn more straight from the experts’ page.